Our complete production line guarantees production capacity from raw materials to finished products

We serve ONE-STOP-SOLUTION to ensure customers efficient and cost-effective purchasing.

We test each piece of magnets to avoid any quality problem for customers.

We offer different types of packaging for customers to keep products & transportation safe.

We work with big customers as well as small ones without MOQ.

We offer all kinds of payment methods to facilitate customers' purchasing habits.

Demagnetization Curves

Demagnetization Curves

Precise micro magnets The department that deals with the cutting of is equipped to cut very small squares with sections up to 0.50mm with a precision of 0.05 mm and very big diameters such as the disks for watch-glass up to a diameter of 45mm. The department planar rectification guarantees flat grinding with parallel sides of all the products we work on such as Rare earth Magnet, all types of ceramics and hard metal. The tolerance margins we guarantee are normally±0.01 mm. but in some particular cases we are able to go down to ±0.005 mm.One of our strongest points is the centreless grinding of extra hard materials with a diameter from 0.10 mm.upto 40mm.with a tolerance margin that can reach a precision of up to±0.001mm. Our micro magnets for cylinders with tiny hole or without hole are appreciated by our customers for their quality and regularity.The machines we use allow us to work both with a static shaping process and with a continuous flow technique according to the sizes required.Our working tools are diamond grinding wheel of different types and grain according to the piece and to the work to carry out,and the roughness of the surfaces are comprised between Ra of 0.2u and 0.5u.

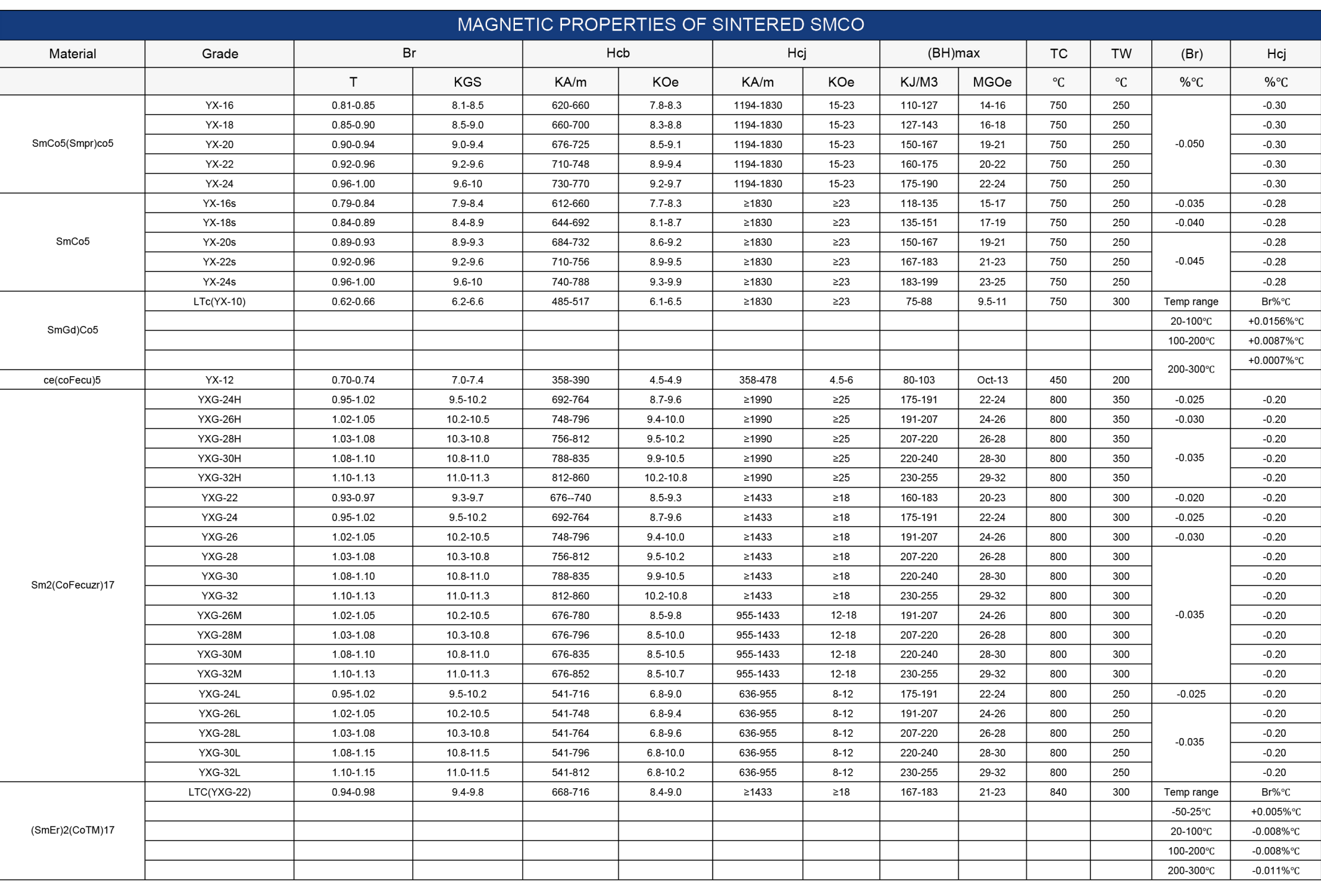

Precise micro magnets The department that deals with the cutting of is equipped to cut very small squares with sections up to 0.50mm with a precision of 0.05 mm and very big diameters such as the disks for watch-glass up to a diameter of 45mm. The department planar rectification guarantees flat grinding with parallel sides of all the products we work on such as Rare earth Magnet, all types of ceramics and hard metal. The tolerance margins we guarantee are normally±0.01 mm. but in some particular cases we are able to go down to ±0.005 mm.One of our strongest points is the centreless grinding of extra hard materials with a diameter from 0.10 mm.upto 40mm.with a tolerance margin that can reach a precision of up to±0.001mm. Our micro magnets for cylinders with tiny hole or without hole are appreciated by our customers for their quality and regularity.The machines we use allow us to work both with a static shaping process and with a continuous flow technique according to the sizes required.Our working tools are diamond grinding wheel of different types and grain according to the piece and to the work to carry out,and the roughness of the surfaces are comprised between Ra of 0.2u and 0.5u. Magnetic Properties

Magnetic Properties

Multi-Magnetization Halbach Array Schematic Diagram

Multi-Magnetization Halbach Array Schematic Diagram