Neodymium magnetic blocks are typically used in numerous applications including motors, medical equipment, sensors, holding applications, electronics, and automotive. Smaller sizes can also be used for simple attaching or holding displays in retail or exhibitions, simple DIY and workshop mounting or holding applications. Their high strength relative to size makes them a very versatile magnet option. Send us inquiries about magnets in your applications, and our sales experts will reply soon!

The selection of the NdFeB magnet in the application will depend on your working environment. If magnets are used at high temperatures, choose alloys with high intrinsic coercivity (HCI). If the alloy is used at a lower temperature (such as room temperature), a higher Br material can be selected. Remember that if magnets are used under adverse conditions, such as repulsive positions in motors, repulsive magnetic fields are used to drive rotors and similar applications, it is recommended to select materials with medium or high coercivity. Applications, where magnetic fields are used to trigger sensors, switches, and similar applications, may use low coercive force magnets. Our standard alloy does not recommend using NdFeB magnets at low temperatures (below 200 ℃); However, we offer custom alloys for these applications. These custom alloys are limited in number because they are very specialized and are produced only in the laboratory. These advanced alloys can reach energy products of more than 52 MGOE at low temperatures. For more information, please call the factory or contact your regional sales manager. Because NdFeB magnets are easy to oxidize quickly, salt mist, brine and hydrogen are very harsh to magnets. If you want to use neodymium iron boron in such environments, please consider sealing magnets. For high-reliability applications, familiarize yourself with the "testing and certification" section to understand the available tests. Some of these tests are used to predict the long-term performance of magnets in magnetic fields. We provide world-class neodymium iron boron alloy, advanced coating, and the ability of rapidly production. In addition, we can manufacture and manufacture the whole assembly according to your requirements, such as rotor or stator assembly, coupling, and seal assembly. Magnetic circuit designs are also available. The permanent magnet is a kind of material that can keep its magnetism after removing the external magnetic field. There are many kinds of permanent magnet materials, and each group has many grades of materials.Neodymium magnets can be formed into many shapes and types:

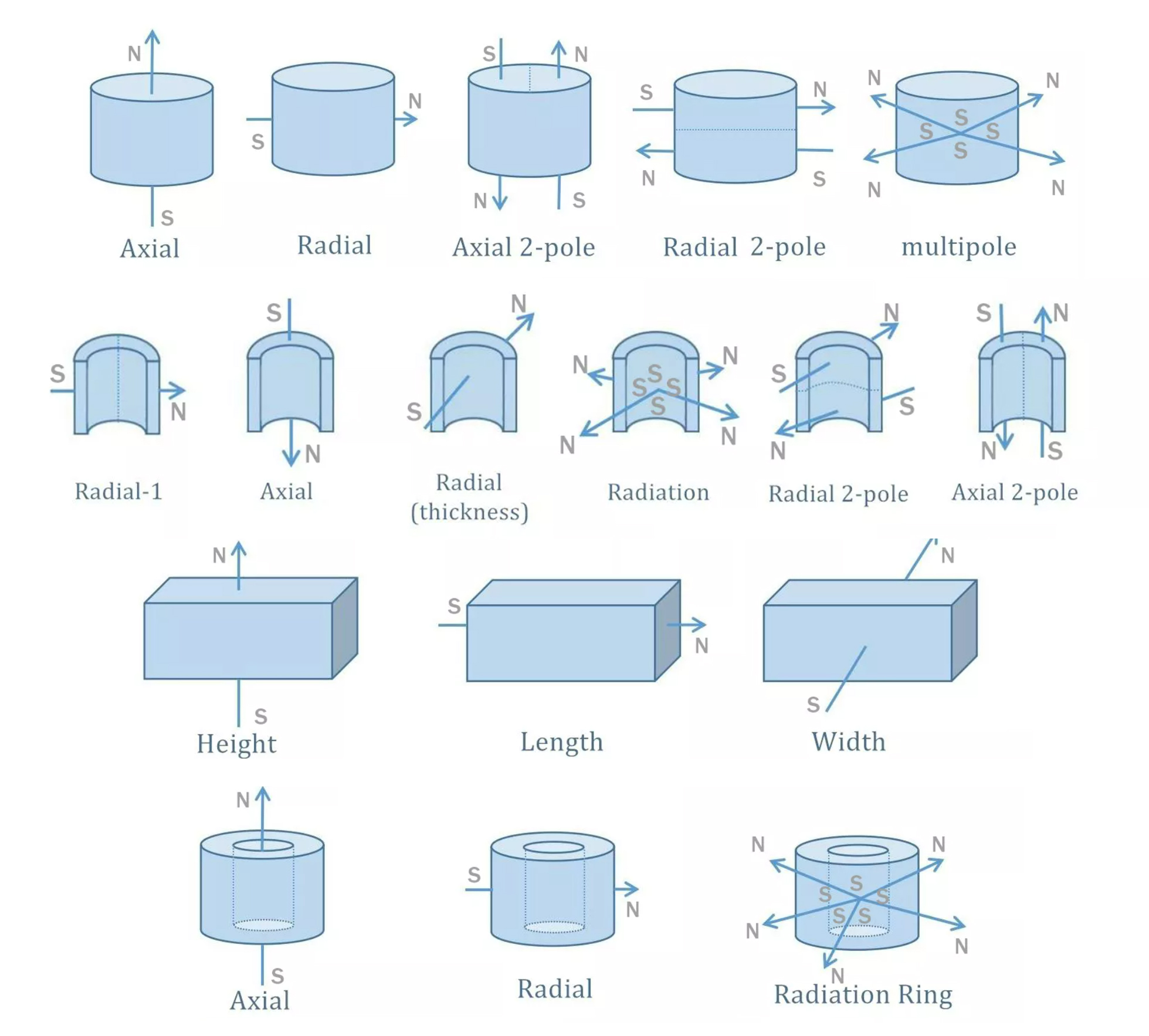

The selection of the NdFeB magnet in the application will depend on your working environment. If magnets are used at high temperatures, choose alloys with high intrinsic coercivity (HCI). If the alloy is used at a lower temperature (such as room temperature), a higher Br material can be selected. Remember that if magnets are used under adverse conditions, such as repulsive positions in motors, repulsive magnetic fields are used to drive rotors and similar applications, it is recommended to select materials with medium or high coercivity. Applications, where magnetic fields are used to trigger sensors, switches, and similar applications, may use low coercive force magnets. Our standard alloy does not recommend using NdFeB magnets at low temperatures (below 200 ℃); However, we offer custom alloys for these applications. These custom alloys are limited in number because they are very specialized and are produced only in the laboratory. These advanced alloys can reach energy products of more than 52 MGOE at low temperatures. For more information, please call the factory or contact your regional sales manager. Because NdFeB magnets are easy to oxidize quickly, salt mist, brine and hydrogen are very harsh to magnets. If you want to use neodymium iron boron in such environments, please consider sealing magnets. For high-reliability applications, familiarize yourself with the "testing and certification" section to understand the available tests. Some of these tests are used to predict the long-term performance of magnets in magnetic fields. We provide world-class neodymium iron boron alloy, advanced coating, and the ability of rapidly production. In addition, we can manufacture and manufacture the whole assembly according to your requirements, such as rotor or stator assembly, coupling, and seal assembly. Magnetic circuit designs are also available. The permanent magnet is a kind of material that can keep its magnetism after removing the external magnetic field. There are many kinds of permanent magnet materials, and each group has many grades of materials.Neodymium magnets can be formed into many shapes and types: -Arc / Segment / Tile / Curved magnets -Eye Bolt magnets -Block magnets -Magnetic Hooks / Hook magnets -Hexagon magnets -Ring magnets -Countersunk and counterbore magnets -Rod Magnets -Cube magnets -Adhesive Magnet -Disc Magnets -Sphere magnets neodymium -Ellipse & Convex Magnets -Other Magnetic Assemblies

| Product Name | N42SH F60x10.53x4.0mm Neodymium Block Magnet | |

| Material | Neodymium-Iron-Boron | |

| Neodymium magnets are a member of the Rare Earth magnet family and are the most powerful permanent magnets in the world. They are also referred to as NdFeB magnets, or NIB, because they are composed mainly of Neodymium (Nd), Iron (Fe) and Boron (B). They are a relatively new invention and have only recently become affordable for everyday use. | ||

| Magnet Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid and Irregular shapes and more. Customized shapes are available | |

| Magnet coating | Neodymium magnets are a composition of mostly Neodymium, Iron and Boron. If left exposed to the elements, the iron in the magnet will rust. To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but nickel is the most common and usually preferred. Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes our magnets much more durable than the more common single nickel plated magnets. Some other options for coating are zinc, tin, copper, epoxy, silver and gold. | |

| Features | The most powerful permanent magnet, offers a great return for cost & performance, have the highest field/surface strength(Br), high coercivity(Hc), can be easily formed into various shapes and sizes. Be reactive with moisture and oxygen, usually supplied by plating (Nickel, Zinc, Passivatation, Epoxy coating, etc.). | |

| Applications | Sensors, motors, filter automobiles, magnetics holders, loudspeakers, wind generators, medical equipments, etc. | |

| Grade & Working Temperature | Grade | Temperature |

| N28-N48 | 80° | |

| N50-N55 | 60° | |

| N30M-N52M | 100° | |

| N28H-N50H | 120° | |

| N28SH-N48SH | 150° | |

| N28UH-N42UH | 180° | |

| N28EH-N38EH | 200° | |

| N28AH-N33AH | 200° | |