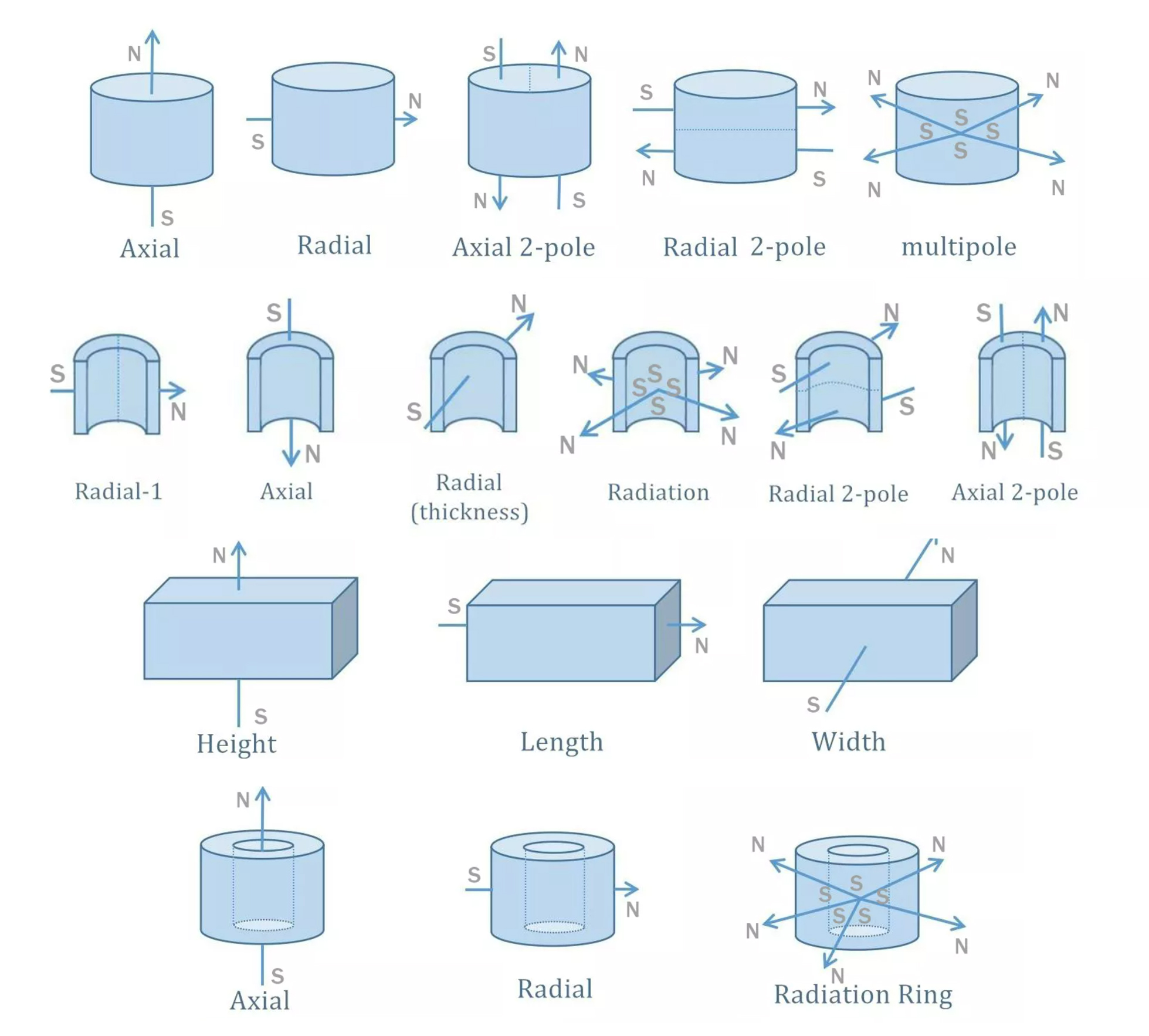

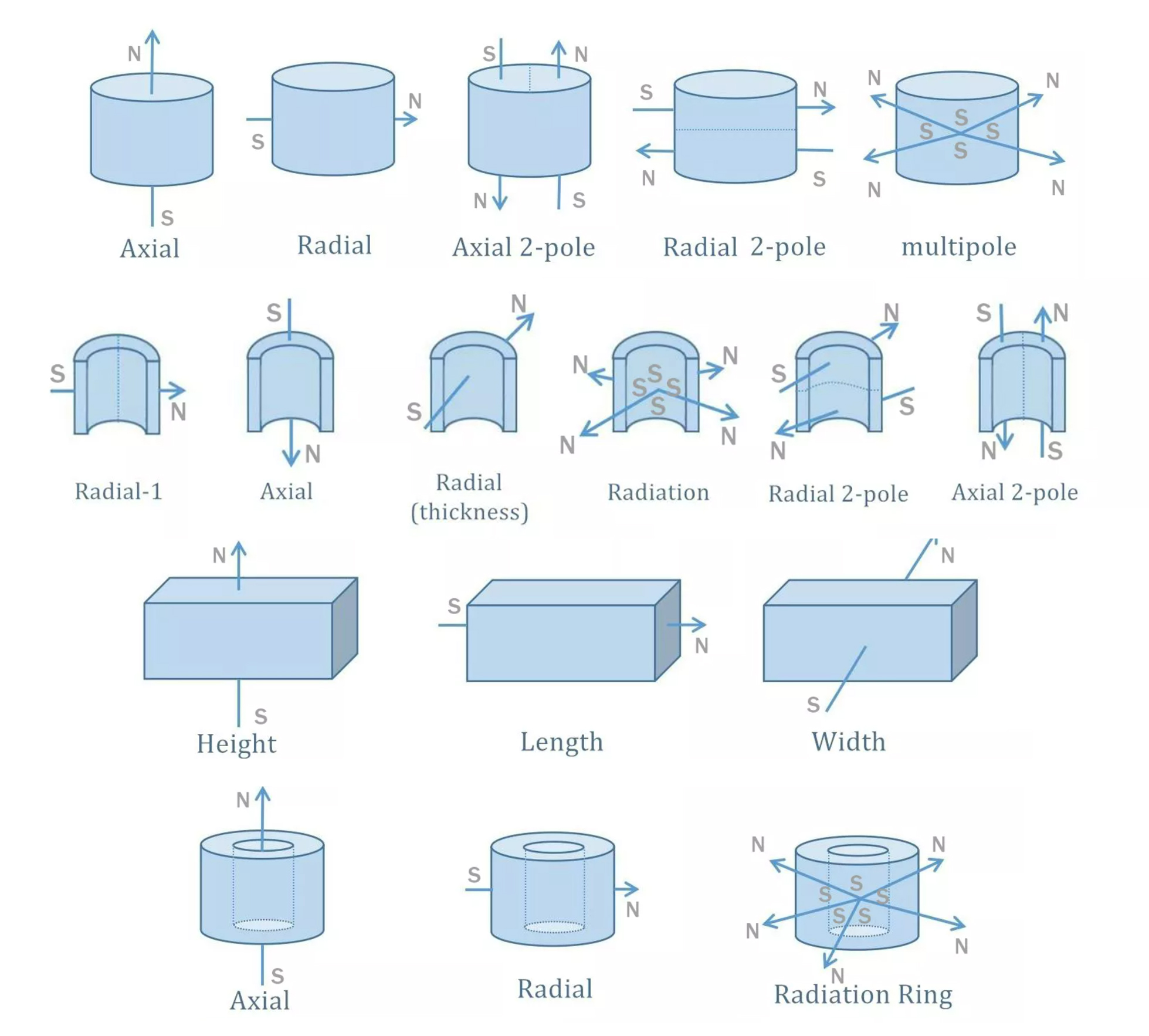

Specification: Material Neodymium-Iron-Boron Performance: Grade N45 Shape: disc, round, circle Surface Gold: (can build all kinds of coatings) 45 MGOe(N45)Neodymium Rare Earth Quadrapolar, HEXAPOLAR, OCTAPOLAR, CONCENTRIC, BIPOLAR Penetration=4mm/0.16” Magnet Width=4mm/0.16" Magnet Thickness = 1.5 mm/0.06" Pull Force = 2 N / 0.2 kgf/ 0.5 lbf No Flux Plate attached No plastic casing Tolerance±0.05mm Operating Temperature Maximum 80°C(can be customized temperature) Engineering Service: As custom magnet manufacturers, engineering is at the heart of our business Valued Service: Internation exhibitions every year in USA and Germany for visiting and meeting