With a hole in the middle

In varieties of Sizes

In wide range of dimensions

Used in motors & rotors

Widely used in speakers

Widely used in educational field

We offer custom services

Variants available

Magnetic Properties Why Honsen Magnetics

Magnetic Properties Why Honsen Magnetics  Applications

Applications Our complete production line guarantees production capacity from raw materials to finished products

We serve ONE-STOP-SOLUTION to ensure customers efficient and cost-effective purchasing.

We test each piece of magnets to avoid any quality problem for customers.

We offer different types of packaging for customers to keep products & transportation safe.

We work with big customers as well as small ones without MOQ.

We offer all kinds of payment methods to facilitate customers' purchasing habits.

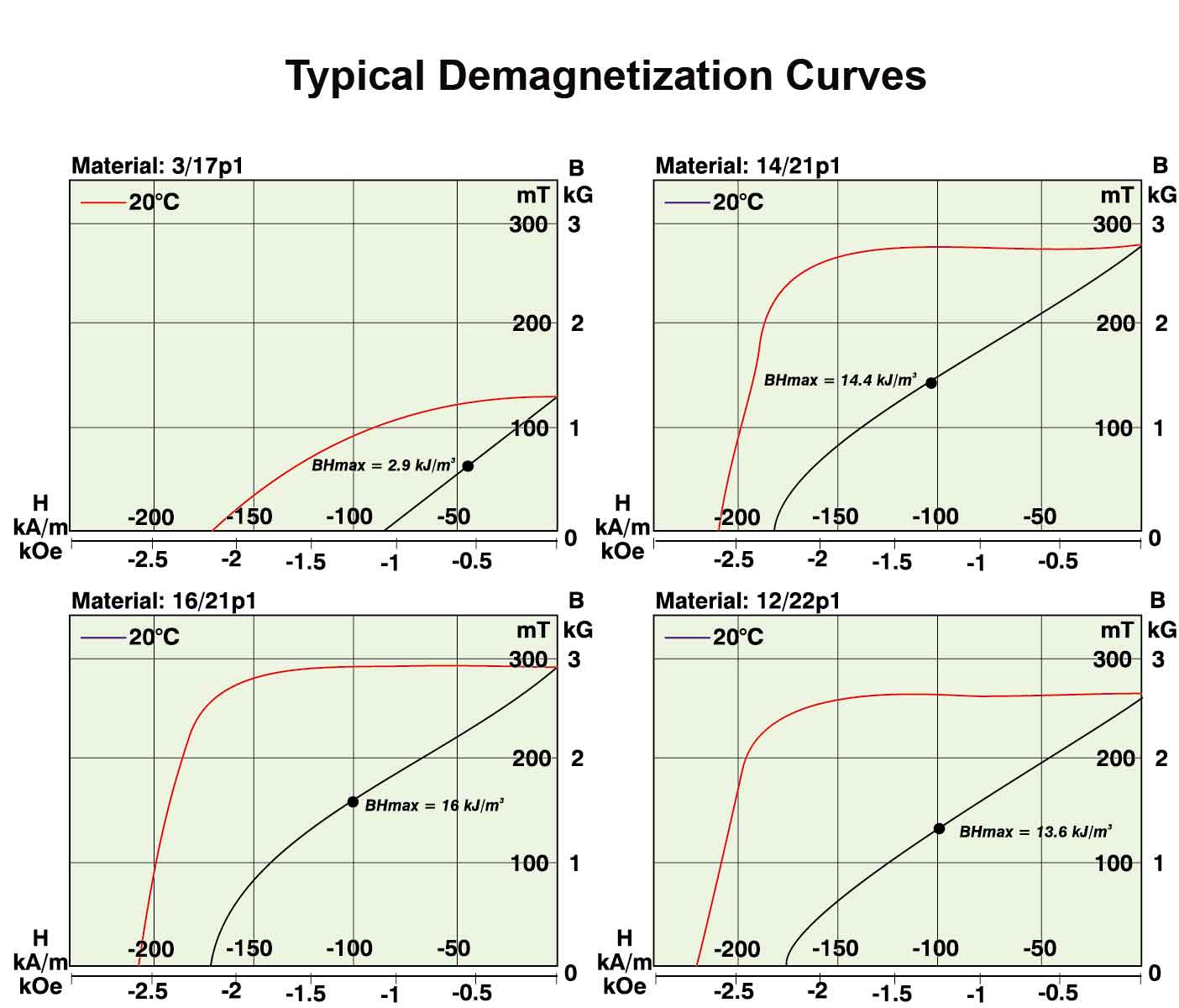

Ferrite Bonded Magnets that utilize an injection molding process can be made by combining a variety of Ferrite powders with Nylon 6, Nylon 12, PPS, and other resins. The ratios between magnetic powders and resins are endless, therefore many grades exist depending on magnetic performance, temperature resistance, and mechanical strength. These materials can be molded directly over or into another polymer or metal component. The shapes and sizes are endless, as are the magnetization patterns that can be achieved either in the molding tool or by utilizing a magnetizing fixture. The following tables list several common grades, however, we have the capability to formulate any desired grade of magnetic material based on customer-specified parameters. Honsen Magnetics produce high-quality & low-price Injection bonded magnets for more than 10 years! Contact our team for your project! Injection Bonded Ferrite Magnets-A modern production process for permanent magnetic materials, it possesses higher magnetic properties compared to conventional ferrite magnets. This process is highly efficient and precise, granting these components special characteristics. The injection molding process has hardness and elasticity, allowing it to be processed into thin rings with ease. Complex shapes and precise tolerances can be achieved with the injection of a mixture of ferrite powder and plastic binder. The material is corrosion-resistant due to the plastic binder that covers the ferrite powder. The density of this material is 3.6-3.8g/cm3 with an operating temperature range of -40°C-130℃. Injection-molded ferrite magnets are available in many forms, such as discs, blocks, rings, arcs, etc. These magnets are widely used in motors, relays, sensors, DC motors, small generators, laser printer magnetic rollers, and air conditioners. Precision plastic parts are commonly used in the fields of appliances, motors, and hardware. Applications: 1, Magnetic rollers in copiers and laser printers 2, Permanent motor magnets in rotors and other components 3, Magnetic rings for aerodynamic parts 4, Convergence magnet for color monitor/TV 5, Binders for PA 6, PA 12, and PPSDemagnetization Curves

Ferrite Bonded Magnets that utilize an injection molding process can be made by combining a variety of Ferrite powders with Nylon 6, Nylon 12, PPS, and other resins. The ratios between magnetic powders and resins are endless, therefore many grades exist depending on magnetic performance, temperature resistance, and mechanical strength. These materials can be molded directly over or into another polymer or metal component. The shapes and sizes are endless, as are the magnetization patterns that can be achieved either in the molding tool or by utilizing a magnetizing fixture. The following tables list several common grades, however, we have the capability to formulate any desired grade of magnetic material based on customer-specified parameters. Honsen Magnetics produce high-quality & low-price Injection bonded magnets for more than 10 years! Contact our team for your project! Injection Bonded Ferrite Magnets-A modern production process for permanent magnetic materials, it possesses higher magnetic properties compared to conventional ferrite magnets. This process is highly efficient and precise, granting these components special characteristics. The injection molding process has hardness and elasticity, allowing it to be processed into thin rings with ease. Complex shapes and precise tolerances can be achieved with the injection of a mixture of ferrite powder and plastic binder. The material is corrosion-resistant due to the plastic binder that covers the ferrite powder. The density of this material is 3.6-3.8g/cm3 with an operating temperature range of -40°C-130℃. Injection-molded ferrite magnets are available in many forms, such as discs, blocks, rings, arcs, etc. These magnets are widely used in motors, relays, sensors, DC motors, small generators, laser printer magnetic rollers, and air conditioners. Precision plastic parts are commonly used in the fields of appliances, motors, and hardware. Applications: 1, Magnetic rollers in copiers and laser printers 2, Permanent motor magnets in rotors and other components 3, Magnetic rings for aerodynamic parts 4, Convergence magnet for color monitor/TV 5, Binders for PA 6, PA 12, and PPSDemagnetization Curves