With a hole in the middle

In varieties of Sizes

In wide range of dimensions

Used in motors & rotors

Widely used in speakers

Widely used in educational field

We offer custom services

Variants available

Magnetic Properties Why Honsen Magnetics

Magnetic Properties Why Honsen Magnetics  Applications

Applications Our complete production line guarantees production capacity from raw materials to finished products

We serve ONE-STOP-SOLUTION to ensure customers efficient and cost-effective purchasing.

We test each piece of magnets to avoid any quality problem for customers.

We offer different types of packaging for customers to keep products & transportation safe.

We work with big customers as well as small ones without MOQ.

We offer all kinds of payment methods to facilitate customers' purchasing habits.

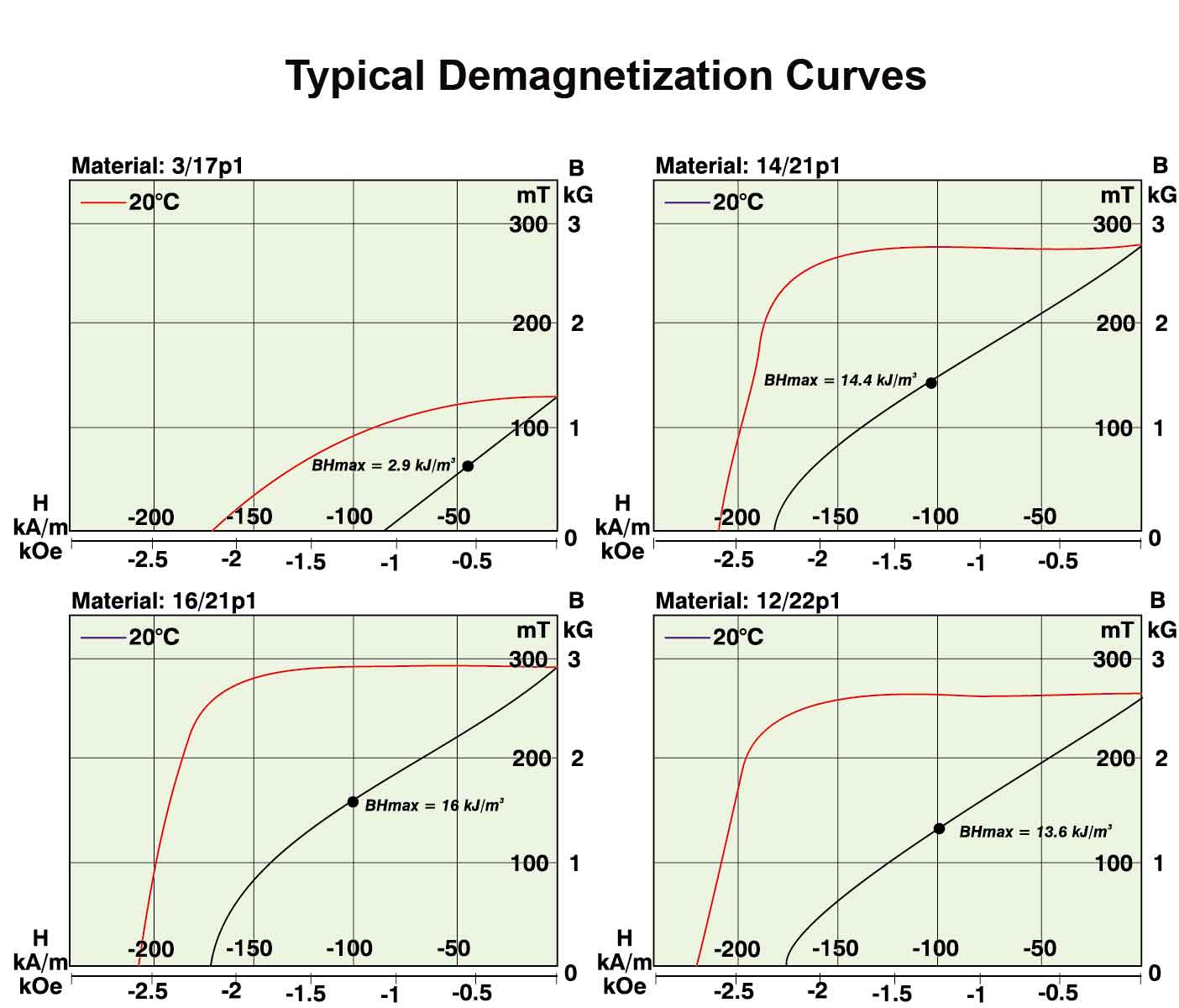

Injection-molded ferrite magnets are a type of permanent ferrite magnet that is manufactured through the injection molding process. Similar to Injection Molded NdFeB Magnets, These magnets are created using a combination of ferrite powders and resin binders, such as PA6, PA12, or PPS, which are then injected into a mold to form a finished magnet with complex shapes and precise dimensions. Compared with injection-molded NdFeB, injection molded Ferrite has a different magnetic compound, which results in lower magnetic properties due to ferrite features, but it costs much less than NdFeB. Injection-molded ferrite magnets are incredibly versatile and can be found in automotive, household appliances, robotics, switches, and sensors. Injection-bonded ferrite magnets boast a range of benefits, including excellent magnetic strength and physical properties. These magnets are also highly cost-effective, as they can be manufactured on a large scale with close dimensional tolerances and require no additional finishing. Honsen Magnetics offers a selection of injection-bonded ferrite magnets that are known for their dependability and practicality. Customers can choose from existing designs or have magnets custom-designed to meet their specific needs.Features: Injection molded ferrite magnets are a great solution for projects requiring complex shapes and high precision. These magnets offer tolerance levels of + - 0.005mm, making them suitable for intricate parts. Furthermore, this technology allows for adjustable magnetic properties and composite molding, with superior mechanical strength compared to sintered magnets. Insert molding also allows magnetic material to be directly molded into other components, without the need for extra assembly. Contact our sales team for your applications! Demagnetization Curves

Injection-molded ferrite magnets are a type of permanent ferrite magnet that is manufactured through the injection molding process. Similar to Injection Molded NdFeB Magnets, These magnets are created using a combination of ferrite powders and resin binders, such as PA6, PA12, or PPS, which are then injected into a mold to form a finished magnet with complex shapes and precise dimensions. Compared with injection-molded NdFeB, injection molded Ferrite has a different magnetic compound, which results in lower magnetic properties due to ferrite features, but it costs much less than NdFeB. Injection-molded ferrite magnets are incredibly versatile and can be found in automotive, household appliances, robotics, switches, and sensors. Injection-bonded ferrite magnets boast a range of benefits, including excellent magnetic strength and physical properties. These magnets are also highly cost-effective, as they can be manufactured on a large scale with close dimensional tolerances and require no additional finishing. Honsen Magnetics offers a selection of injection-bonded ferrite magnets that are known for their dependability and practicality. Customers can choose from existing designs or have magnets custom-designed to meet their specific needs.Features: Injection molded ferrite magnets are a great solution for projects requiring complex shapes and high precision. These magnets offer tolerance levels of + - 0.005mm, making them suitable for intricate parts. Furthermore, this technology allows for adjustable magnetic properties and composite molding, with superior mechanical strength compared to sintered magnets. Insert molding also allows magnetic material to be directly molded into other components, without the need for extra assembly. Contact our sales team for your applications! Demagnetization Curves