Ceramic Rings

Ferrite Ring Magnets

With a hole in the middle

Disc Ferrite Magnets

Ceramic Disc Magnets

In varieties of Sizes

Ceramic Blocks

Rectangular Ferrite Magnet

In wide range of dimensions

Ferrite Arc/ Segment Magnets

Ceramic Segment

Used in motors & rotors

Ferrite Rod Magnets

Cylindrical Ferrite Magnets

Widely used in speakers

Ceramic Horseshoe Magnet

U-shaped Ferrite Magnet

Widely used in educational field

Customized Ferrite Magnets

Irregular-shaped Ceramic

We offer custom services

Ferrite Holding Pots

For holding & Lifting

Variants available

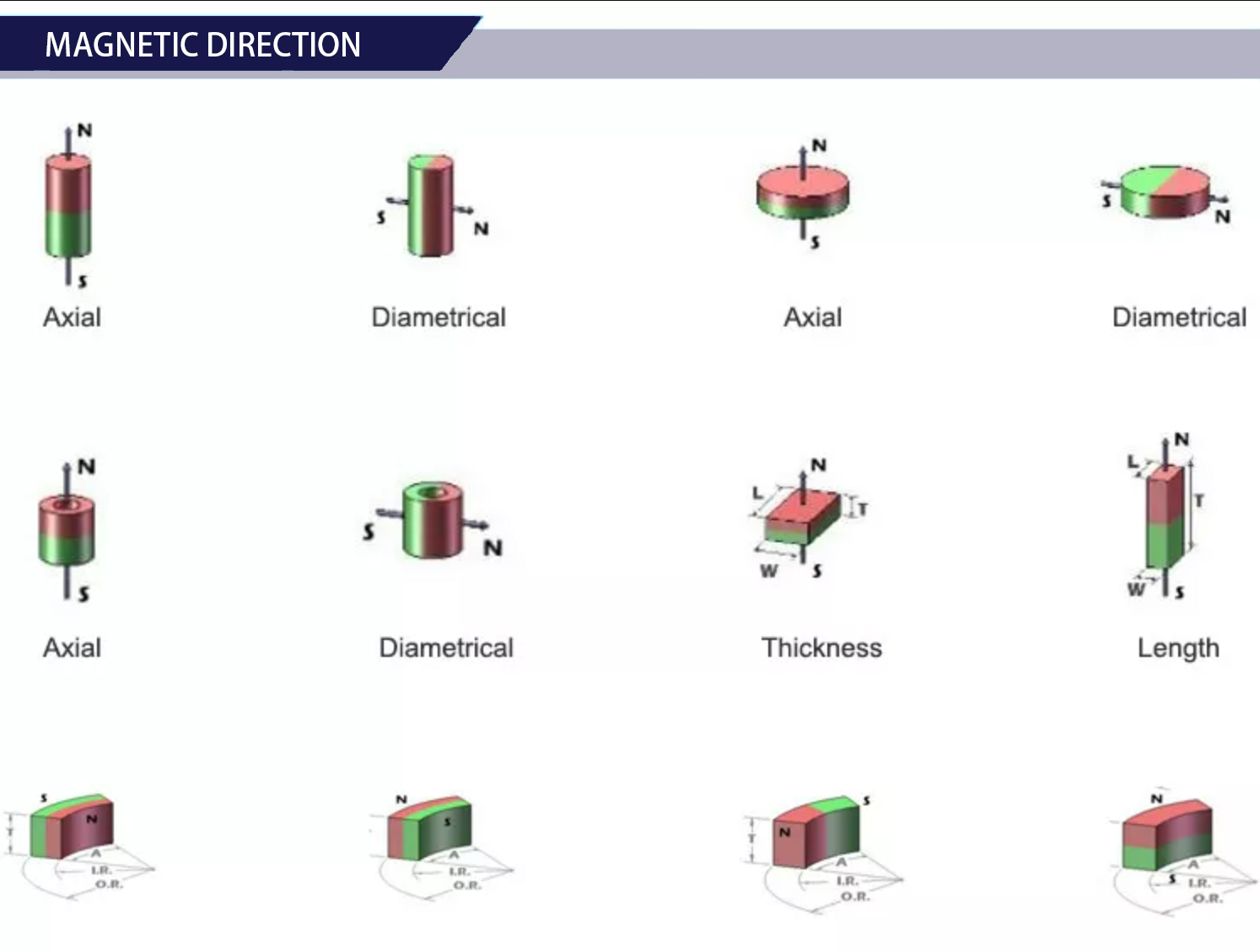

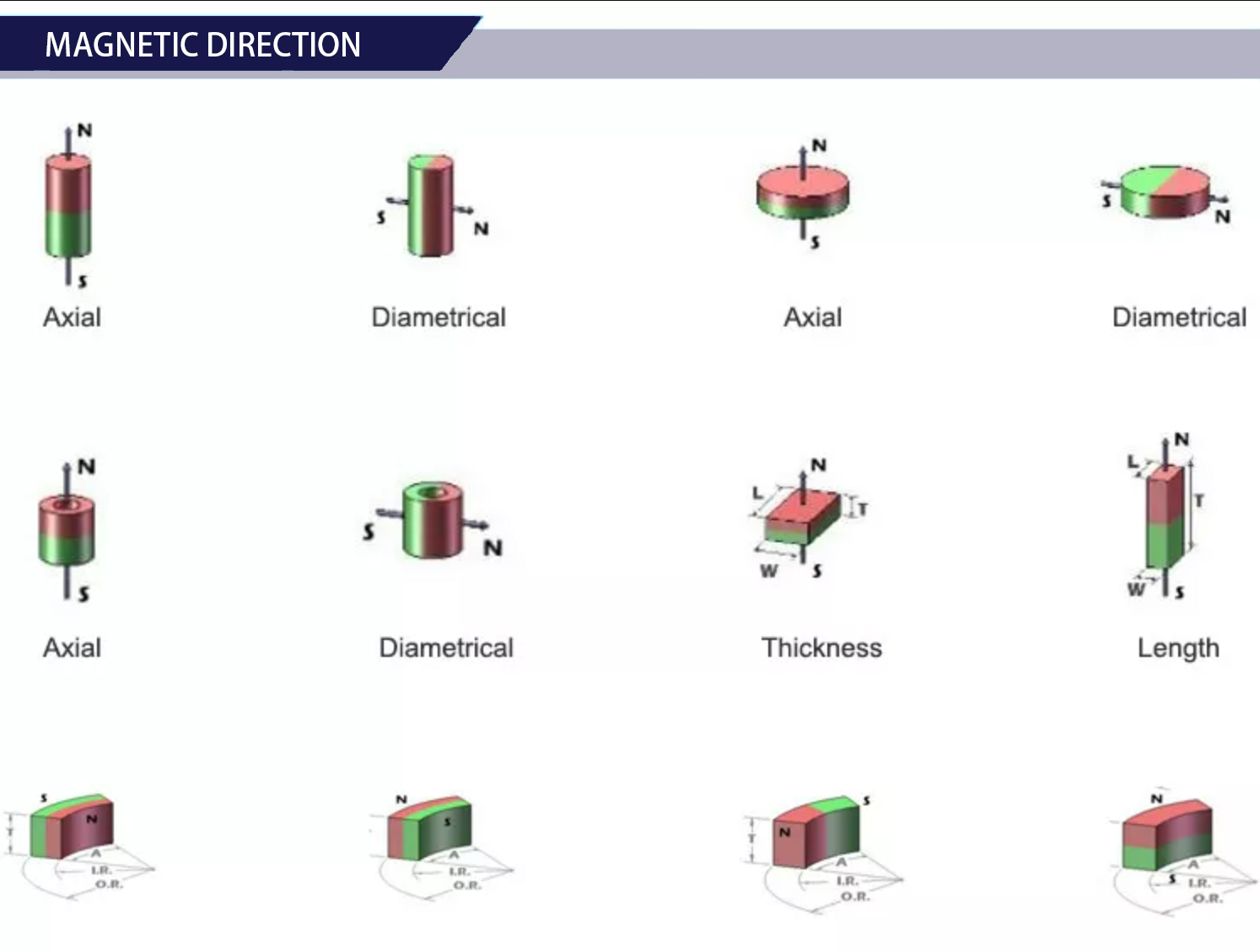

Magnetic Direction Magnetic Properties

Magnetic Direction Magnetic Properties  Why Honsen Magnetics

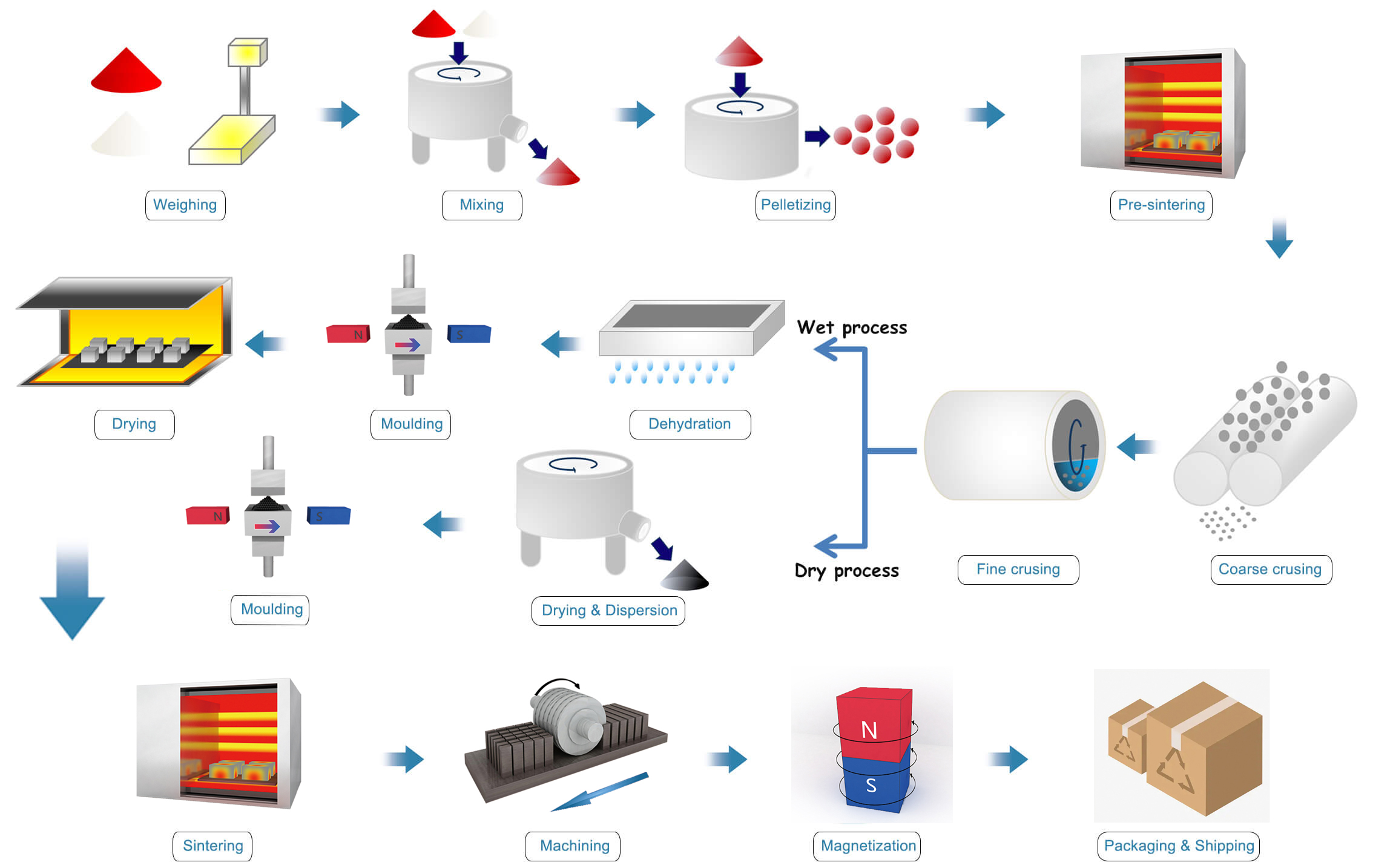

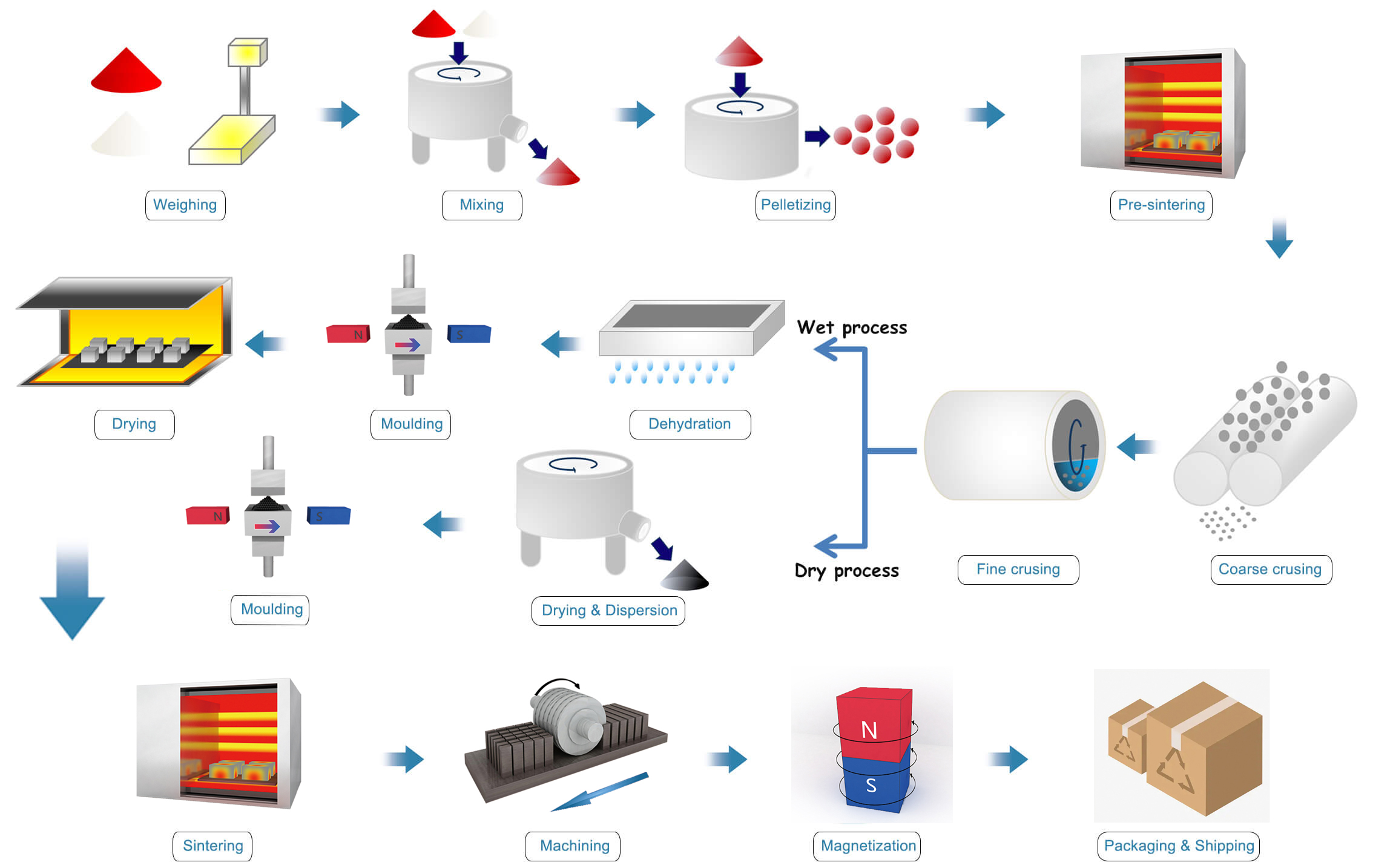

Why Honsen Magnetics  Manufacturing Process of Ferrite Magnets

Manufacturing Process of Ferrite Magnets  Applications

Applications Our complete production line guarantees production capacity from raw materials to finished products

We serve ONE-STOP-SOLUTION to ensure customers efficient and cost-effective purchasing.

We test each piece of magnets to avoid any quality problem for customers.

We offer different types of packaging for customers to keep products & transportation safe.

We work with big customers as well as small ones without MOQ.

We offer all kinds of payment methods to facilitate customers' purchasing habits.

| Name: | Dry Pressed Isotropic Customized Ferrite Magnet |

| Dimension: | Customized |

| Diameter: | Customized |

| Grade: | Y10, Y25,Y30, Y30BH, Y30H-1, Y33, Y33H, Y35, Y35BH |

| Thickness: | Customized |

| Processing: | Bending, Welding, Decoiling, Cutting, Punching, Mould |

| Features: | Produced by powder metallurgy with low remanence and low recovery permeability |

| The magnetic circuit structure with high coercivity and strong |

| Anti-demagnetization ability is especially suitable for dynamic working conditions |

| The material is hard and brittle and can be used for cutting with emery tools |

| The main raw material is oxide, so it is not easy to corrode |

| Working temperature: - 40 ℃ to+200 ℃ |

| Applications: | Motors, speakers, toys, handicrafts, sensors, etc |

We are a professional magnet manufacturer providing quality and reliable products. With a decade of experience, we offer a wide range of magnets such as neodymium, ferrite, alnico, and more. Our magnets are designed to meet the needs of any application. We are committed to delivering quality products with superior service and competitive prices. Let us help you find the right magnet for your project. We are dedicated to providing our customers with the highest quality magnets available. Our manufacturing process ensures that our magnets are of the highest quality and that they meet your exact specifications. We also offer custom design services to meet your unique requirements. We are confident that our magnets will meet your needs and provide lasting performance. Our team is always available to answer any questions you may have. Contact us today to learn more about our wide selection of magnets and how we can help.Magnetic materials are the basic functional materials for the electronics industry. As an important part of magnetic materials, permanent magnetic materials play an important role in the electronics industry, information industry, motorcycle industry, electric tools industry, automotive industry, etc. Permanent magnet ferrite material is a functional material that generates a magnetic field. Due to its low raw material price and relatively simple production process, its finished product price is relatively low compared with other magnets. The main raw materials of ferrite magnet are oxides, so it is not affected by the environment or chemicals (except strong acid) and does not need to be plated on the surface. It is a widely used permanent magnet material, which is made by powder metallurgy and can be divided into two kinds, barium material (Ba) and strontium material (Sr), and into two types, anisotropic and isotropic. It is a permanent magnet material that is not easy to demagnetize and corrode, with a working temperature of up to 250 ℃, which is harder and brittle and can be cut and processed with diamond sand, etc. The alloy die can be formed at one time. This product is mainly used in crafts, adsorption accessories, toys, motors, speakers, etc. It is manufactured by powder metallurgy - the chemical composition is Ba/Sr O6 FeO - it is harder and brittle - not easy to demagnetize - very good corrosion resistance - is low price, a rich source - good temperature stability - widely used permanent magnet. The production process of permanent magnet ferrite: Batching --> Pre-firing --> Crushing --> Ball Milling --> Powder Making --> Dry Pressing Magnetic Field Forming / Dry Pressing Forming / Wet Pressing Magnetic Field Forming --> Sintering --> Machining --> Inspection --> Packaging

Magnetic Direction Magnetic Properties

Magnetic Direction Magnetic Properties  Why Honsen Magnetics

Why Honsen Magnetics  Manufacturing Process of Ferrite Magnets

Manufacturing Process of Ferrite Magnets  Applications

Applications