Detailed parameters

Product Flow Chart

Why Choose Us

Company Show

Feedback

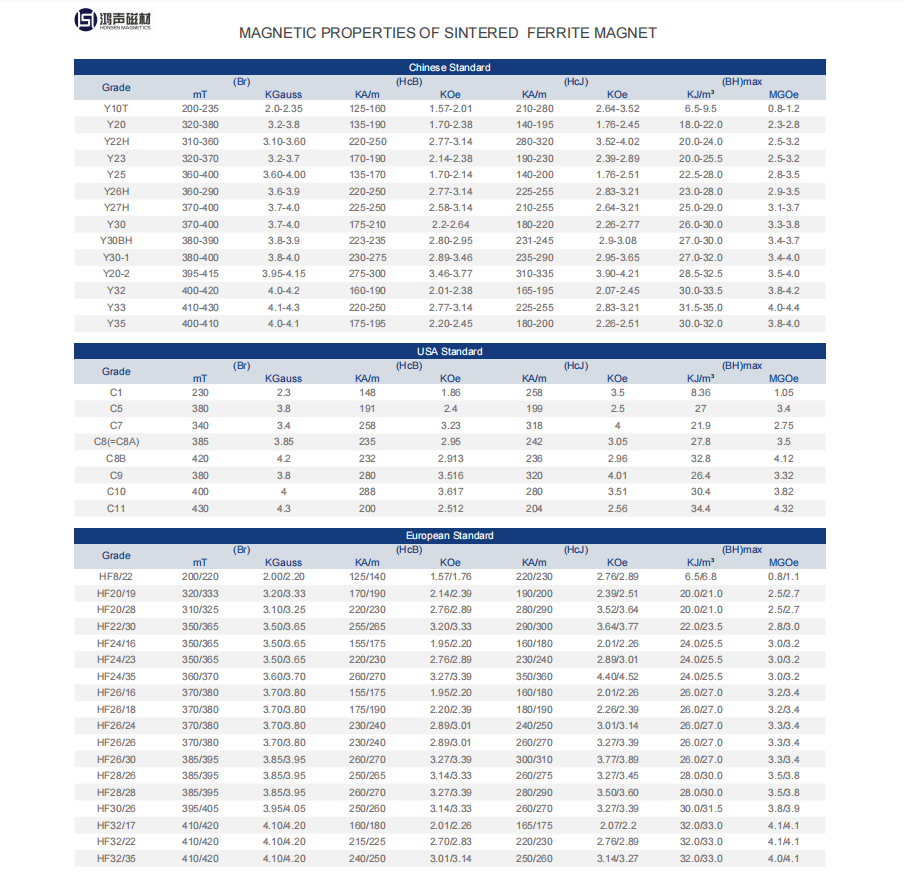

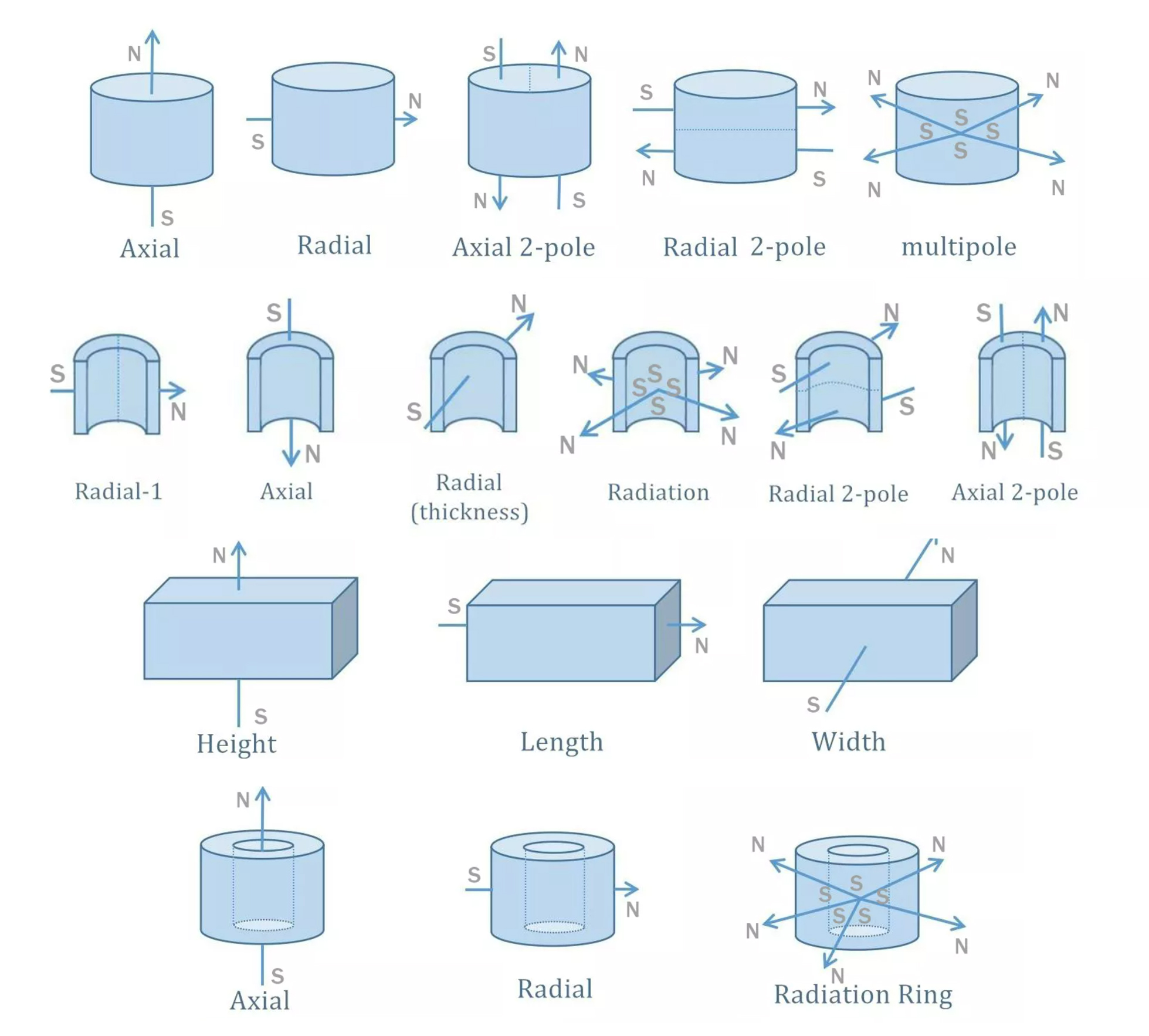

Use our magnets for school science projects and other educational projects. 1. ltem Name: super strong ceramic magnets 2.Material: Ferrite (ceramic) magnets(hard ferrite magnet 3.Various shapes on offer: block, round, disc, ring, arc and segment.Virtually any shape of super strong ceramic magnets C1 C5 C8 disk hard ferrite magnet for sale can be made to your reguirements! 4.Types: lsotropic ferrite magnets and Anisotropic ferrite magnets 5. Max. working temperature for various grades Grade: Max Operating Temperature Y10T, Y30, Y30BH, Y35 and more 250℃(482F) 6. Orientations of super strong ceramic magnets. >Isotropic ferrite magnets are not oriented and can be magnetized in any direction. >Anisotropic ferrite magnets are different, they are all orientedin the manufacturing direction, and should be magnetized in the direction oforientation. Super Strong Ceramic Disk Y35 Hard Ferrite Refrigerator Magnet for Sale 7. Packing of super strong ceramic magnets:Export standard foam-filled cartons supplied standard.Tailored packaging offered per customer request.Packages appropriate to both air and sea shipment available. 8. Production Procedure: >Bydryprocess, can produce isotropic & anisotropic magnets.The tool can be changed and developed easily. >Bywet process, only anisotropic magnets can be produced.ltis complicated to change the tool and the tooling charge is much higher.

Use our magnets for school science projects and other educational projects. 1. ltem Name: super strong ceramic magnets 2.Material: Ferrite (ceramic) magnets(hard ferrite magnet 3.Various shapes on offer: block, round, disc, ring, arc and segment.Virtually any shape of super strong ceramic magnets C1 C5 C8 disk hard ferrite magnet for sale can be made to your reguirements! 4.Types: lsotropic ferrite magnets and Anisotropic ferrite magnets 5. Max. working temperature for various grades Grade: Max Operating Temperature Y10T, Y30, Y30BH, Y35 and more 250℃(482F) 6. Orientations of super strong ceramic magnets. >Isotropic ferrite magnets are not oriented and can be magnetized in any direction. >Anisotropic ferrite magnets are different, they are all orientedin the manufacturing direction, and should be magnetized in the direction oforientation. Super Strong Ceramic Disk Y35 Hard Ferrite Refrigerator Magnet for Sale 7. Packing of super strong ceramic magnets:Export standard foam-filled cartons supplied standard.Tailored packaging offered per customer request.Packages appropriate to both air and sea shipment available. 8. Production Procedure: >Bydryprocess, can produce isotropic & anisotropic magnets.The tool can be changed and developed easily. >Bywet process, only anisotropic magnets can be produced.ltis complicated to change the tool and the tooling charge is much higher.