Neodymium magnetic blocks are typically used in numerous applications including motors, medical equipment, sensors, holding applications, electronics and automotive. Smaller sizes can also be used simple attaching or holding displays in retail or exhibitions, simple DIY and workshop mounting or holding applications. Their high strength relative to size makes them a very versatile magnet option.

Neo magnets are known for their high-temperature resistance, making them durable and functional at temperatures above 200 ° C. This quality makes it an ideal choice for heavy industrial applications. However, sintered neodymium is sensitive to oxidation and can cause corrosion, so magnets are usually coated with nickel to protect them. Honsen Magnetics provides world-class Sintered Iron Boron Neodymium magnets with advanced coating and rapid production capacity. In addition, we can manufacture the whole assembly according to your requirements, such as magnetic rotor or stator assembly, magnetic coupling, and seal assembly. Magnetic circuit designs are also available. The permanent magnet is a kind of material that can keep its magnetism after removing the external magnetic field. There are many kinds of permanent magnet materials, and each group has many grades of materials. Sintered NdFeB magnets have very high magnetic properties, excellent magnetic properties, and good environmental temperature performance. They have stronger mechanical strength than SM co magnets and are less brittle than ceramics and AlNiCo magnets. However, sintered NdFeB magnets are easily corroded. Therefore, when used for a long time, the special coating must be used for protection, such as Zn, Ni, Ni Cu Ni, or epoxy resin. In general, sintered NdFeB magnets require some finishing to meet the final tolerances. We produce a variety of high-energy neodymium iron boron materials. Our neodymium iron boron magnets have an excellent dollar value in terms of price/performance per unit of energy products, allowing small shapes and sizes with high magnetic properties. In addition, our low-cost manufacturing resources will greatly reduce the cost of your application. Neodymium magnets can be formed into many shapes and types:

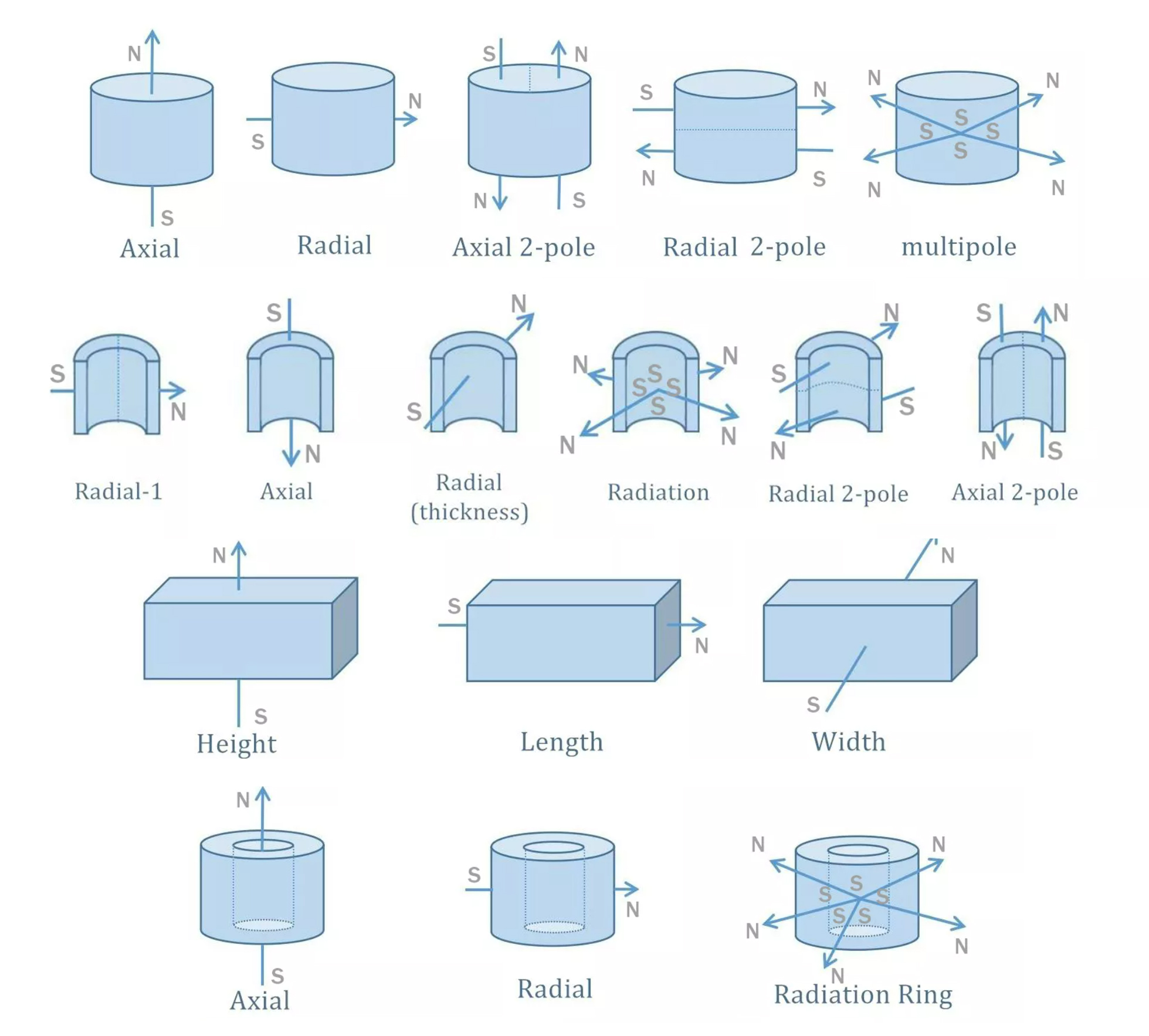

Neo magnets are known for their high-temperature resistance, making them durable and functional at temperatures above 200 ° C. This quality makes it an ideal choice for heavy industrial applications. However, sintered neodymium is sensitive to oxidation and can cause corrosion, so magnets are usually coated with nickel to protect them. Honsen Magnetics provides world-class Sintered Iron Boron Neodymium magnets with advanced coating and rapid production capacity. In addition, we can manufacture the whole assembly according to your requirements, such as magnetic rotor or stator assembly, magnetic coupling, and seal assembly. Magnetic circuit designs are also available. The permanent magnet is a kind of material that can keep its magnetism after removing the external magnetic field. There are many kinds of permanent magnet materials, and each group has many grades of materials. Sintered NdFeB magnets have very high magnetic properties, excellent magnetic properties, and good environmental temperature performance. They have stronger mechanical strength than SM co magnets and are less brittle than ceramics and AlNiCo magnets. However, sintered NdFeB magnets are easily corroded. Therefore, when used for a long time, the special coating must be used for protection, such as Zn, Ni, Ni Cu Ni, or epoxy resin. In general, sintered NdFeB magnets require some finishing to meet the final tolerances. We produce a variety of high-energy neodymium iron boron materials. Our neodymium iron boron magnets have an excellent dollar value in terms of price/performance per unit of energy products, allowing small shapes and sizes with high magnetic properties. In addition, our low-cost manufacturing resources will greatly reduce the cost of your application. Neodymium magnets can be formed into many shapes and types: -Arc / Segment / Tile / Curved magnets -Eye Bolt magnets -Block magnets -Magnetic Hooks / Hook magnets -Hexagon magnets -Ring magnets -Countersunk and counterbore magnets -Rod Magnets -Cube magnets -Adhesive Magnet -Disc Magnets -Sphere magnets neodymium -Ellipse & Convex Magnets -Other Magnetic Assemblies

| Product Name | N42SH F60x10.53x4.0mm Neodymium Block Magnet | |

| Material | Neodymium-Iron-Boron | |

| Neodymium magnets are a member of the Rare Earth magnet family and are the most powerful permanent magnets in the world. They are also referred to as NdFeB magnets, or NIB, because they are composed mainly of Neodymium (Nd), Iron (Fe) and Boron (B). They are a relatively new invention and have only recently become affordable for everyday use. | ||

| Magnet Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid and Irregular shapes and more. Customized shapes are available | |

| Magnet coating | Neodymium magnets are a composition of mostly Neodymium, Iron and Boron. If left exposed to the elements, the iron in the magnet will rust. To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but nickel is the most common and usually preferred. Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes our magnets much more durable than the more common single nickel plated magnets. Some other options for coating are zinc, tin, copper, epoxy, silver and gold. | |

| Features | The most powerful permanent magnet, offers a great return for cost & performance, have the highest field/surface strength(Br), high coercivity(Hc), can be easily formed into various shapes and sizes. Be reactive with moisture and oxygen, usually supplied by plating (Nickel, Zinc, Passivatation, Epoxy coating, etc.). | |

| Applications | Sensors, motors, filter automobiles, magnetics holders, loudspeakers, wind generators, medical equipments, etc. | |

| Grade & Working Temperature | Grade | Temperature |

| N28-N48 | 80° | |

| N50-N55 | 60° | |

| N30M-N52M | 100° | |

| N28H-N50H | 120° | |

| N28SH-N48SH | 150° | |

| N28UH-N42UH | 180° | |

| N28EH-N38EH | 200° | |

| N28AH-N33AH | 200° | |

If the magnet is clamped between two mild steel (ferromagnetic) plates, the magnetic circuit is good (there are some leaks on both sides). But if you have two NdFeB Neodymium Magnets, which are arranged side by side in an N-S arrangement (they will be very strongly attracted in this way), you have a better magnetic circuit, with potentially higher magnetic pull, almost no air gap leakage, and the magnet will be close to its maximum possible performance (assuming that the steel will not be magnetically saturated). Further considering this idea, considering the checkerboard effect (-N-S-N-S -, etc.) between two low-carbon steel plates, we can get a maximum tension system, which is only limited by the ability of the steel to carry all the magnetic flux.